Glass Cosmetic Packaging Wholesale

From sleek minimalism to intricate detailing, our glass containers can not only protects your cosmetic products but also tells a visual story that resonates with your brand’s unique aesthetic.

We provide customization options for you to precisely match your requirements of glass cosmetic containers:

- Shapes: jar, bottle, and tube.

- Capacities: from small 1 ml to 5 ml, 15 ml, 30 ml, 50 ml, 60 ml, 100 ml, 150 ml and above 200 ml

- Colors: clear, black, green, amber, blue, frosted and other custom colors.

- Accessories: pump, lid, sprayer

By Shape

The choice of the glass cosmetic container’s shape may depend on the cosmetic product, brand aesthetics, user convenience, and product protection.

Glass Cosmetic Jar

Glass Cosmetic Bottle

It often has a cylindrical or rectangular shape with a narrow neck and a variety of cap or dispenser options. It’s ideal for liquid products like serums, toners, or foundations, and can be equipped with various pumps, droppers, or sprayers.

Glass Cosmetic Tube

By Usage

Glass packaging helps maintain product integrity while providing an upscale presentation, making it the go-to choice for high-quality cosmetic products.

Glass Perfume Bottle

Glass Lip Balm Container

Glass Cream Jar

Glass Mascara Tube

Glass Lotion Bottle

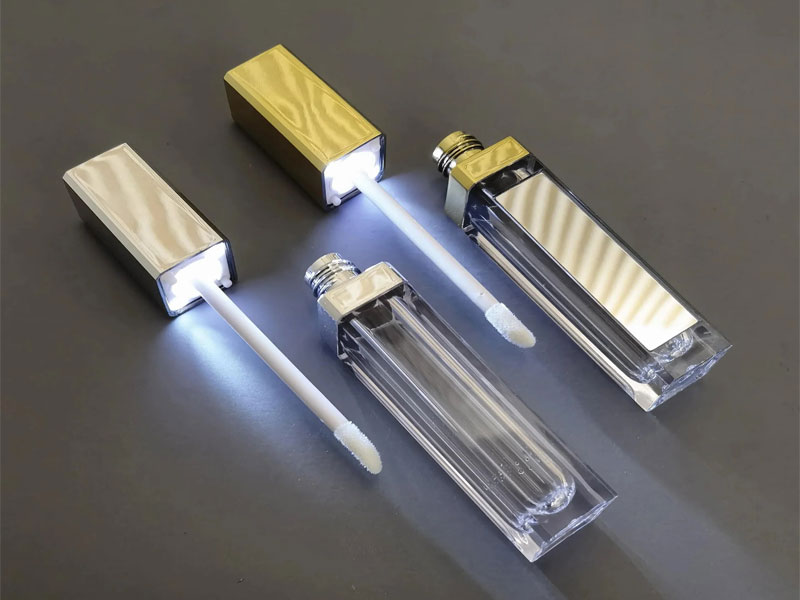

Glass Lip Gloss Tube

By Size

1-5ml

- Typically used for small quantities of high-concentration products like serums or essential oils.

- Common for sample sizes or travel-sized products.

5-15ml

- Suitable for small to medium-sized products, such as eye creams, lip balms, or small facial serums.

- Common for travel-sized items and targeted skincare treatments.

30-50ml

- A versatile range that can accommodate various products, including moisturizers, toners, and some facial serums.

- Popular for regular use, and the size is often seen in standard skincare routines.

60-120ml (1-2 oz)

- Commonly used for larger skincare products like cleansers, body lotions, and medium-sized facial serums.

- Suitable for products intended for longer-term use.

150-200ml

- Larger sizes suitable for body care products such as body lotions, and hair care products.

- Ideal for products used on a larger surface area.

Over 200 ml

- Typically used for large bottles of body lotion, shower gels, or hair care products.

- Common for products used frequently or over an extended period.

By Color

Clear Glass

- Transparent glass with a crystal-clear appearance.

- Allows full visibility of the product inside, giving a premium look.

- Ideal for serums, perfumes, and skincare products that benefit from an elegant display.

Black Glass

- Opaque, sleek, and elegant black-colored glass.

- Prevents all light exposure, preserving the integrity of light-sensitive formulations.

- Used for luxury and high-end beauty products.

Green Glass

- A refreshing, nature-inspired green-tinted glass.

- Enhances a natural and eco-friendly branding appeal while offering some UV protection.

- Often used for organic and botanical-based cosmetics.

White Glass

- A clean, modern, and opaque white glass.

- Offers a sleek, minimalist design while ensuring protection from light exposure.

- Ideal for premium skincare, serums, and high-end beauty lines.

Amber Glass

- A warm, golden-brown tinted glass.

- Provides UV protection, preserving light-sensitive formulations.

- Commonly used for essential oils, herbal extracts, and organic skincare products.

Cobalt Blue Glass

- A deep, vibrant blue-colored glass.

- Offers UV protection while providing a distinctive, eye-catching appearance.

- Frequently used for essential oils, serums, and specialty cosmetic formulations.

Pink Glass

- Soft pink-tinted glass that adds a luxurious and feminine touch.

- Visually appealing, premium feel, enhances brand identity.

- Popular for perfumes, serums, and luxury beauty products.

Frosted Glass

- Semi-opaque glass with a soft, matte finish.

- Provides a premium, sophisticated look while slightly obscuring the contents.

- Perfect for serums, moisturizers, and high-end skincare products.

Accessories

Pump

These glass cosmetic bottles come with a pump dispenser, allowing controlled dispensing of the cosmetic product.

Lid

These glass cosmetic jars typically come with a screw-on or snap-on lid, providing a secure seal.

Sprayer

Equipped with a sprayer or atomizer, these bottles are designed for products that need to be sprayed rather than poured or pumped.

Manufacturing Process

Melting

- The raw materials are mixed and melted in a furnace at high temperatures (around 1700°C).

- The melton glass is subsequently purified to eliminate impurities.

Forming

- Blow-and-Blow Process:

- Air is blown into a parison (a hollow glass tube), shaping it into a mold.

- Press-and-Blow Process:

- A plunger presses the glass into a mold, forming the container.

Annealing

- The formed glass containers undergo a controlled cooling process called annealing. This helps relieve internal stresses and ensures uniform thickness.

Surface Treatment

- Frosting or Etching:

- For a frosted or textured appearance.

- Decorating:

- If required, the glass containers can be decorated with labels, coatings, or printed designs.