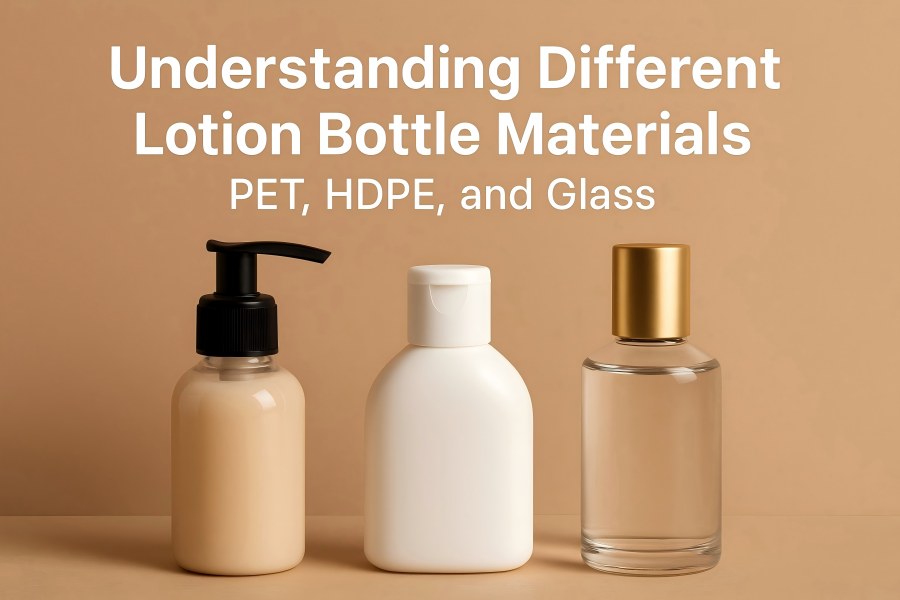

In personal care and cosmetics, packaging is more than mere containment. A lotion bottle shapes a product’s identity, influencing how consumers perceive and value it. The material choice affects durability, recyclability, cost, and environmental impact. Glass, High-Density Polyethylene (HDPE), and Polyethylene Terephthalate (PET) are popular choices.

Each material offers distinct strengths in clarity, chemical resistance, and sustainability. Understanding these differences helps brands, developers, and eco-conscious consumers choose wisely. This article explores the properties, manufacturing, environmental impact, and best uses of PET, HDPE, and Glass lotion bottles to guide smarter material selection.

Role of Packaging in Lotion Products

It’s critical to comprehend the rationale behind lotion bottle design before evaluating materials. Lotion packaging serves multiple purposes:

- Protection: The container shields the product from light, oxygen, and contaminants that can degrade its quality.

- Usability: It should allow smooth, controlled dispensing—whether through pumps, squeezes, or flip caps.

- Aesthetics: Packaging communicates brand value and market positioning—luxury glass signals elegance, while lightweight plastics suggest practicality and portability.

- Sustainability: Growing consumer awareness pushes brands to adopt recyclable, refillable, or eco-friendly packaging materials.

Each material—PET, HDPE, and Glass—responds differently to these needs, balancing functionality, safety, and sustainability in distinct ways.

PET (Polyethylene Terephthalate) Bottles

PET is a thermoplastic polyester made from ethylene glycol and terephthalic acid. It’s widely recognized for its clarity, strength, and recyclability, making it the dominant material for beverage bottles and cosmetic packaging alike. In lotions, PET bottles combine lightweight convenience with an appealing, glass-like transparency that showcases the product inside.

| Pros | Cons |

| Clear and glossy appearance | Can deform under high heat |

| Lightweight and impact-resistant | Limited UV and oxygen barrier |

| Cost-efficient production | Not ideal for hot filling |

| Fully recyclable material | Environmental concerns if unrecycled |

| Compatible with most lotion types | Slight permeability over long storage |

Physical and Chemical Properties

| Property | Description |

| Appearance | Clear and glossy; can be tinted or frosted for design flexibility |

| Density | Approximately 1.38 g/cm³ (lighter than glass but denser than HDPE) |

| Impact Resistance | High; resists cracking even under moderate pressure |

| Barrier Properties | Excellent resistance to oils, moisture, and gases |

| Thermal Stability | Performs best under 60–70°C; may warp under extreme heat |

| Recyclability | Fully recyclable; part of the #1 plastic recycling stream |

PET’s structure gives it a strong molecular alignment, which contributes to its rigidity and high tensile strength. It’s also naturally resistant to water and many chemicals, ensuring the lotion remains uncontaminated.

Manufacturing Process

A two-step injection stretch blow molding (ISBM) procedure is used to create PET bottles:

- Preform Creation: To create a tiny, thick preform that resembles a test tube, PET resin is melted and poured into a mold.

- Blow Molding: To give the preform its final shape, it is heated and stretched using high-pressure air inside a bottle mold.

This process aligns the polymer chains for maximum strength and clarity while maintaining flexibility for custom shapes and branding designs.

Best Applications

PET lotion bottles are ideal for retail-ready skincare products, travel-sized lotions, and mass-market cosmetics where clarity and lightweight convenience are key. Brands targeting modern, eco-conscious consumers can also opt for rPET (recycled PET), which offers the same performance with a smaller environmental footprint.

HDPE (High-Density Polyethylene) Bottles

HDPE is a petroleum-based thermoplastic polymer that has a high strength-to-density ratio. Unlike PET, HDPE has a semi-crystalline, opaque structure that prioritizes durability over clarity. It’s one of the most common materials used in personal care packaging because it’s resistant to chemicals, flexible, and affordable.

| Pros (Advantages) | Cons (Limitations) |

| Excellent impact resistance | Limited product visibility |

| Strong chemical resistance | Surface easily scratched |

| Lightweight and portable | Less premium appearance |

| Low production cost | |

| Widely recyclable |

Physical and Chemical Properties

| Property | Description |

| Appearance | Opaque, typically white or colored |

| Density | Around 0.95 g/cm³ (lighter than PET and glass) |

| Impact Resistance | Excellent; maintains shape after squeezing or dropping |

| Barrier Properties | Good resistance to moisture, but moderate gas barrier |

| Thermal Stability | Withstands temperatures up to ~120°C |

| Recyclability | Fully recyclable; part of the #2 plastic recycling stream |

HDPE’s molecular branching makes it less rigid but more impact-resistant than PET. It doesn’t crack easily under stress and performs well in a wide temperature range, making it ideal for everyday, travel, or outdoor skincare products.

Manufacturing Process

Most HDPE lotion bottles are made through extrusion blow molding (EBM):

- Extrusion: Melted HDPE resin is extruded into a tube (parison).

- Molding: The tube is clamped into a mold, inflated, and cooled into shape.

This process supports various wall thicknesses and shapes, from soft squeeze bottles to rigid pump containers.

Best Applications

HDPE is the preferred material for everyday skincare bottles, body lotions, sunblock, and children’s skincare products, where durability and low cost outweigh aesthetic considerations. It’s also popular for refillable and bulk lotion dispensers, thanks to its structural flexibility and resistance to leaks or cracks.

Glass Lotion Bottles

Glass has been used in cosmetic packaging for centuries and continues to be associated with luxury, purity, and environmental responsibility. With its silica (sand), soda ash, and limestone composition, glass provides unparalleled chemical inertness and a superior tactile feel. Unlike plastics, glass doesn’t leach or react with the lotion, preserving its quality for longer periods.

| Pros | Cons |

| Premium, luxurious appearance | Fragile and easily breakable |

| Chemically stable and non-reactive | Heavy and costly to ship |

| Infinitely recyclable material | High manufacturing cost |

| Provides UV protection | Not suitable for travel |

| Excellent temperature resistance | Requires careful handling |

Physical and Chemical Properties

| Property | Description |

| Appearance | Crystal-clear or tinted; smooth, glossy surface |

| Density | Around 2.5 g/cm³ (heavier than PET or HDPE) |

| Chemical Resistance | Excellent; inert to almost all skincare ingredients |

| Thermal Resistance | Can tolerate both hot and cold temperatures |

| Recyclability | 100% recyclable without quality loss |

| Durability | High hardness but fragile under impact |

Glass’s nonporous and inert nature prevents oxygen, UV, or chemicals from affecting the lotion’s stability—making it ideal for high-end, sensitive, or natural formulations.

Manufacturing Process

Glass bottles are produced through blow-and-blow or press-and-blow techniques:

- Batch Melting: Silica, soda, and limestone are melted at ~1,500°C.

- Forming: A parison is formed out of the molten glass before it is blown into a mold.

- Annealing and Finishing: The bottle is gradually cooled to relieve internal stresses and polished for clarity.

This process allows for a variety of designs, colors, and finishes—from frosted and tinted bottles to embossed luxury branding.

Best Applications

Glass lotion bottles are favored by luxury skincare brands, essential oil lotions, and eco-friendly companies emphasizing purity and sustainability. They are perfect for premium serums, facial lotions, and boutique formulations where visual elegance and chemical stability justify higher cost and weight.

Comparative Analysis: PET vs. HDPE vs. Glass

| Attribute | PET | HDPE | Glass |

| Transparency | High (clear, glossy) | Opaque or semi-translucent | High; customizable tinting |

| Weight | Light (~1.38 g/cm³) | Very light (~0.95 g/cm³) | Heavy (~2.5 g/cm³) |

| Durability | Shatter-resistant | Highly impact-resistant | Fragile under impact |

| Chemical Resistance | Good | Excellent | Excellent |

| Thermal Resistance | Moderate (up to ~70°C) | High (up to ~120°C) | Very high |

| Cost | Low–Moderate | Low | High |

| Recyclability | Excellent (#1 plastic) | Excellent (#2 plastic) | Infinite |

| Environmental Impact | Moderate; depends on recycling | Low; energy-efficient to produce | High energy cost but fully recyclable |

| Aesthetic Appeal | Modern and clear | Practical and utilitarian | Premium and elegant |

| Common Use Cases | Retail lotions, travel sizes | Family skincare, sunblock, refills | Luxury skincare, natural products |

This table highlights the trade-offs between visual appeal, durability, and sustainability. PET offers a sleek look and lightweight design, HDPE ensures rugged performance at low cost, and glass defines premium sustainability and brand prestige.

Sustainability and Environmental Considerations

Brands cannot ignore package sustainability in the eco-aware market of today. The environmental profile of PET, HDPE, and glass differs significantly in terms of energy use, recyclability, and lifecycle impact.

PET: High Recyclability but Fossil-Based

PET’s recyclability is excellent—it can be reprocessed into rPET for new bottles or textile fibers. However, incorrect disposal adds to the pollution caused by microplastics, and it comes from nonrenewable petroleum sources. Innovations such as bio-based PET (derived from plant ethanol) and closed-loop recycling systems are improving its environmental footprint.

HDPE: Reusable and Energy-Efficient

Among polymers, HDPE has one of the least negative effects on the environment. It produces less greenhouse gasses and uses less energy than glass. Additionally, HDPE containers are often refillable or reusable, extending their lifecycle. Its widespread recyclability (plastic code #2) ensures high recovery rates in many regions.

Glass: Fully Recyclable but Energy-Intensive

While glass is 100% recyclable without quality loss, its production and transport are energy-intensive due to high melting temperatures and weight. However, recycled glass (cullet) significantly reduces this energy demand, making post-consumer recycled (PCR) glass a greener choice for sustainable brands.

The Refill and Reuse Trend

An emerging trend in skincare packaging is the refillable system—using durable outer bottles (often glass or thick HDPE) paired with refill pods made of lightweight PET or HDPE. This hybrid model reduces waste while maintaining a premium aesthetic, allowing brands to balance environmental goals with consumer convenience.

Design and Branding Implications

Material choice also shapes a brand’s image:

- PET aligns with modern, affordable, and youthful branding. Its clarity allows color play, making it popular for vibrant, trendy skincare lines.

- HDPE suits functional and family-oriented brands, emphasizing practicality and safety.

- Glass conveys heritage, elegance, and purity, favored by high-end or eco-luxury labels.

Finishes, embossing, and cap compatibility (pumps, sprays, droppers) further enhance brand distinction. A PET or HDPE bottle with a metallic pump or matte label can elevate perceived value without increasing cost dramatically.

Choosing the Right Material: Factors to Consider

Selecting between PET, HDPE, and glass requires balancing performance, cost, and sustainability. Key decision factors include:

- Product Formulation: Sensitive, oil-based, or natural lotions pair best with glass or HDPE.

- Target Market: Premium lines favor glass; mass-market and travel products lean toward PET or HDPE.

- Distribution Environment: HDPE suits rough handling; glass fits boutique or shelf display.

- Sustainability Goals: Recycled or bio-based PET and HDPE reduce carbon footprint.

- Aesthetic Vision: Clarity (PET), opacity (HDPE), or luxury (Glass) define brand identity.

No single material dominates every aspect; successful packaging often integrates multiple materials or hybrid systems to meet diverse needs.

Future Innovations in Lotion Bottle Materials

The future of skincare packaging is evolving toward circular design and material innovation. New technologies are reshaping how PET, HDPE, and glass interact with sustainability trends:

- Bio-Based Plastics: Companies are developing plant-derived PET and HDPE alternatives.

- Chemical Recycling: Converts plastics back into raw monomers, ensuring infinite recyclability.

- Lightweight Glass: Advances in tempered glass manufacturing reduce weight and breakage risk.

- Smart Packaging: Integration of QR codes and refill indicators encourages recycling behavior.

- Post-Consumer Resin (PCR): Increasingly used by major brands to meet sustainability pledges.

These innovations reflect a global movement toward reducing waste, improving recyclability, and enhancing material performance across the cosmetic packaging industry.