Spray bottles are standard tools in households and industries, used for various purposes, from gardening to cleaning. However, they often stop working correctly, resulting from a clogged nozzle or a malfunctioning spray mechanism. Diagnosing and fixing these issues can save you the hassle and expense of replacing them prematurely.

This guide will walk you through the steps to troubleshoot and repair a non-functioning spray bottle, ensuring it returns to working condition efficiently.

Initial Checks

Before delving into more intricate repairs, start with some basic checks to diagnose why your spray bottle isn’t functioning:

- Inspect the Nozzle: Look for any visible signs of clogs or dirt. Sometimes, debris or dried residue can block the nozzle, preventing the spray mechanism from working.

- Check for Air Blockages: Ensure air can flow freely through the spray mechanism. Air blockages can occur if the bottle is overfilled or the pump mechanism is faulty.

These initial assessments can often quickly pinpoint common issues, allowing for more straightforward fixes before proceeding to more detailed troubleshooting steps.

Cleaning the Nozzle

Cleaning the nozzle of your spray bottle is a crucial step in resolving issues with its functionality. Here’s how to effectively clean the nozzle:

- Disassembly: Carefully unscrew or pull off the nozzle, depending on the bottle’s design. Be mindful of any small parts like springs or triggers.

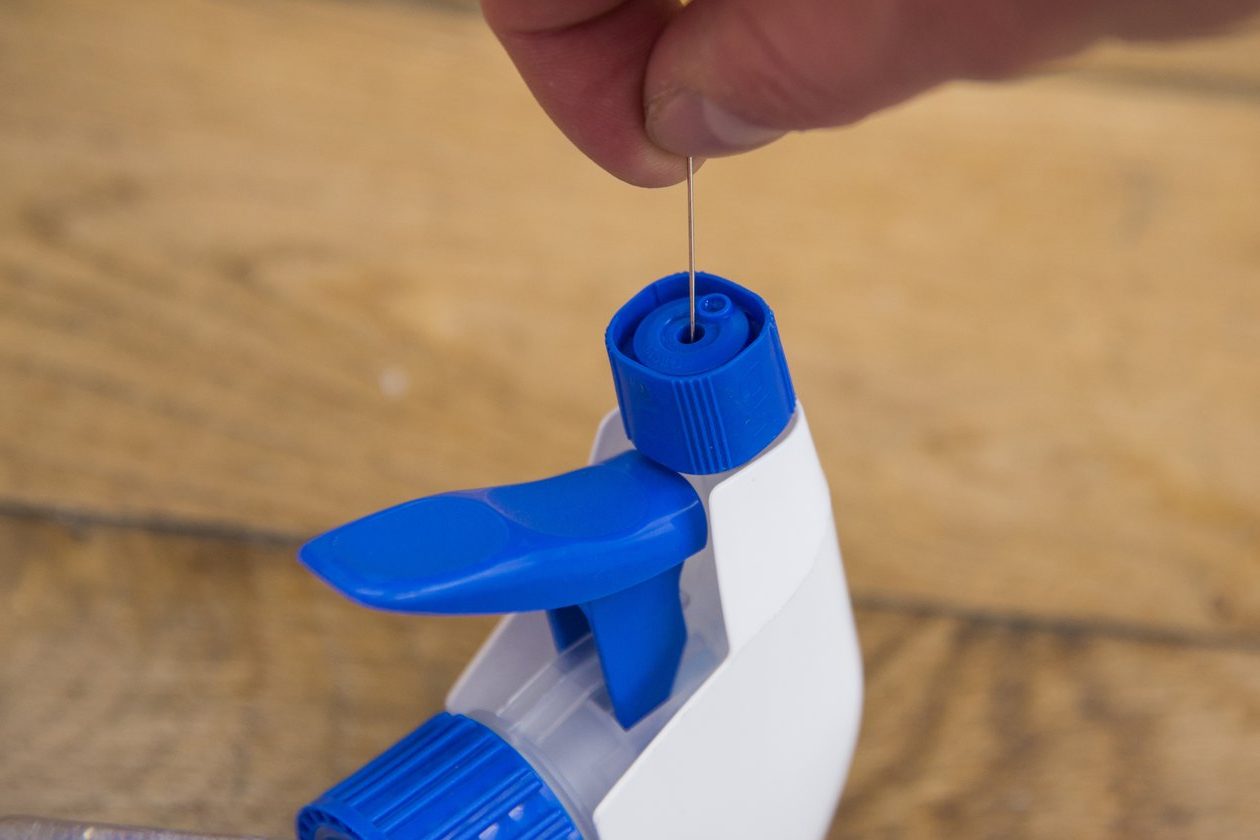

- Soaking and Scrubbing: Soak the nozzle in warm, soapy water or a vinegar solution for a few minutes. Use a small brush or a pin to clear debris from the nozzle opening.

- Rinsing: After scrubbing, thoroughly rinse the nozzle under running water to remove all soap or vinegar.

- Reassembly: Once clean and dry, reassemble the nozzle and reattach it to the bottle. Ensure all components are securely fastened.

This process can remove any clogs or buildup, restoring the functionality of your spray bottle.

Troubleshooting the Pump

If the spray bottle still isn’t working after cleaning the nozzle, the next step is to troubleshoot the pump:

- Pump Inspection: Examine the pump for any visible damage or wear. Check for broken or misaligned parts, which could affect its function.

- Lubrication: If the pump action is stiff or unresponsive, applying a small amount of silicone-based lubricant can help. Ensure the lubricant is compatible with the type of pump mechanism.

- Check for Air Leaks: Ensure the pump is securely attached to the bottle and there are no cracks or leaks in the pump housing or tube. Air leaks prevent the pump from creating enough suction to dispense the liquid.

Addressing these issues can often restore the pump’s functionality, making your spray bottle work like new again.

Checking and Refilling the Reservoir

When troubleshooting a non-functioning spray bottle, it’s essential to check and possibly refill the reservoir:

- Liquid Level: Ensure there’s enough liquid in the reservoir. A low level can affect the pressure and ability to spray.

- Proper Dilution: Verify that the liquid is diluted correctly according to the product’s requirements. Over-concentrated solutions can clog the nozzle or damage the pump mechanism.

These simple checks can resolve issues related to poor spray performance and ensure that the spray bottle operates efficiently.

Advanced Tips

For those looking to go beyond essential maintenance and troubleshooting of a spray bottle, consider these advanced tips:

- Replacement Parts: If cleaning and adjusting do not fix the issue, consider replacing parts like the pump or nozzle. Replacement parts are often available from the manufacturer or specialty stores.

- Periodic Maintenance: Establish a routine cleaning schedule for spray bottles, mainly if used frequently or with potentially clogging substances like oils or chemicals.

- Upgrade Options: If you frequently encounter issues with standard spray bottles, consider upgrading to a higher quality or professional-grade model designed for more durability and better performance.

These steps help to ensure the service life and efficiency of spray bottles and reduce the need for frequent replacement and maintenance.

Conclusion

Fixing a spray bottle that won’t spray involves a series of straightforward steps, from simple checks like inspecting the nozzle and ensuring it’s not clogged, to more in-depth maintenance like cleaning and lubricating the pump mechanism.

Regular cleaning and proper use can significantly extend the life of your spray bottles, saving time and resources. If issues persist, consider replacing worn parts or upgrading to a higher-quality spray bottle for better durability and performance.