In the cosmetics industry, packaging is key to drawing in customers and communicating a brand’s identity. Cosmetic packaging, especially glass bottles known for their premium look and durability, often requires unique printing methods to stand out on store shelves.

This article explores five popular printing methods for cosmetic glass bottles, each offering distinct advantages, disadvantages, and applications.

Five Printing Methods Comparison

Aspect | UV Printing | Screen Printing | Hot Stamping | Laser Etching | Digital Printing |

Durability | High durability; resistant to fading and scratching | Moderate durability; can be prone to scratching | High durability; foil tends to stay intact | Extremely durable; creates permanent engravings | Moderate durability; subject to wear with frequent handling |

Colors | Offers a wide range of colors, including gradients | Limited color range, usually single or multi-color designs | Typically limited to metallic colors like gold or silver | Generally monochromatic (grey or white) | Can support full-color prints |

Texture | Produces a smooth texture | Can produce raised textures depending on the mesh pattern | Smooth, with raised effects due to the foil | Creates engraved textures | Smooth surface |

Design Complexity | Supports complex and intricate designs | Works best with simple designs and bold graphics | Typically used for bold logos or simple text | Ideal for simple text and graphic designs | Ideal for complex graphics and high-resolution prints |

Setup Costs | High setup costs due to UV equipment and inks | Moderate setup costs for mesh screens and inks | High setup costs due to foil materials and stamping equipment | High setup costs due to laser equipment | Lower setup costs compared to other methods |

Applications | Common for high-end cosmetic bottles and detailed branding | Common for logos, simple graphics, and text on cosmetic bottles | Used for luxury branding and eye-catching designs | Often used for permanent markings and serial numbers | Suitable for customization and intricate branding |

Production Speed | Rapid curing process allows for fast production | Depends on the number of colors and design complexity | Generally slower due to the heat transfer process | Fast for simple designs, can be slower for detailed etching | Fast production with high-resolution printing |

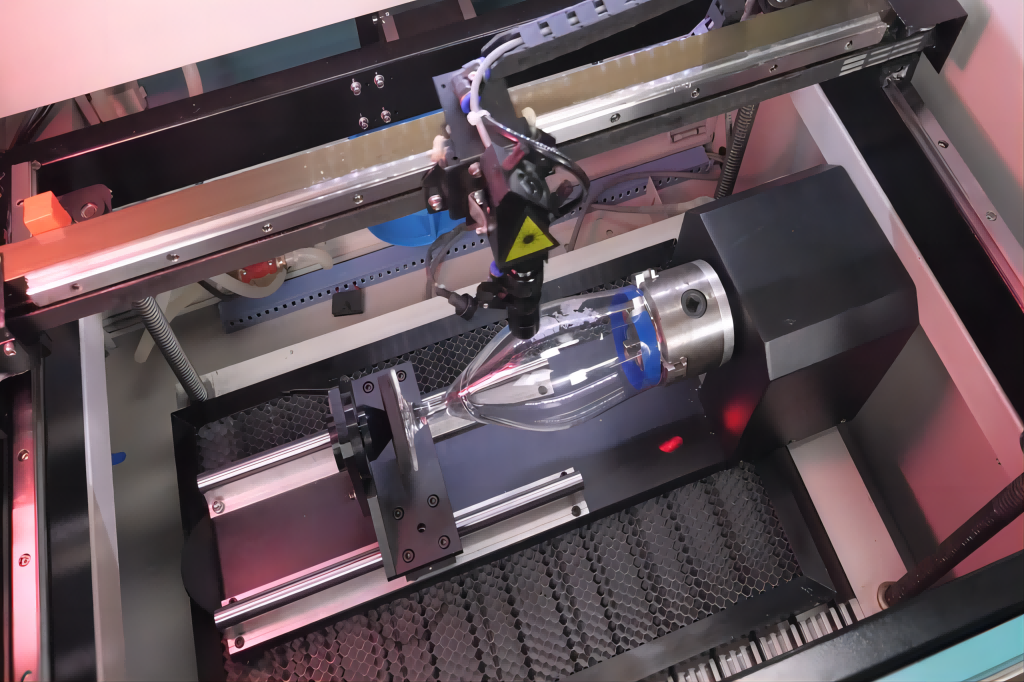

UV Printing

Cosmetic glass bottles utilizing UV printing employ ultraviolet light to harden ink, resulting in vivid and long-lasting designs. This technique supports detailed patterns and a broad spectrum of colors, such as gradients.

UV printing is celebrated for its robust resistance to fading and scratching, making it perfect for premium cosmetic packaging. Nonetheless, it demands specialized machinery and is energy-demanding, which can increase initial costs and raise environmental issues.

Pros | Cons |

|

|

Screen Printing

Cosmetic glass bottles with screen printing employ a mesh screen to transfer ink onto the glass. This approach works well for straightforward designs, such as logos and text.

Screen printing is moderately durable and offers a variety of textures, depending on the mesh used. It’s cost-effective for single-color designs but has a limited color range compared to other methods. Setup costs are moderate, but solvent-based inks used in screen printing can have an environmental impact.

Pros | Cons |

|

|

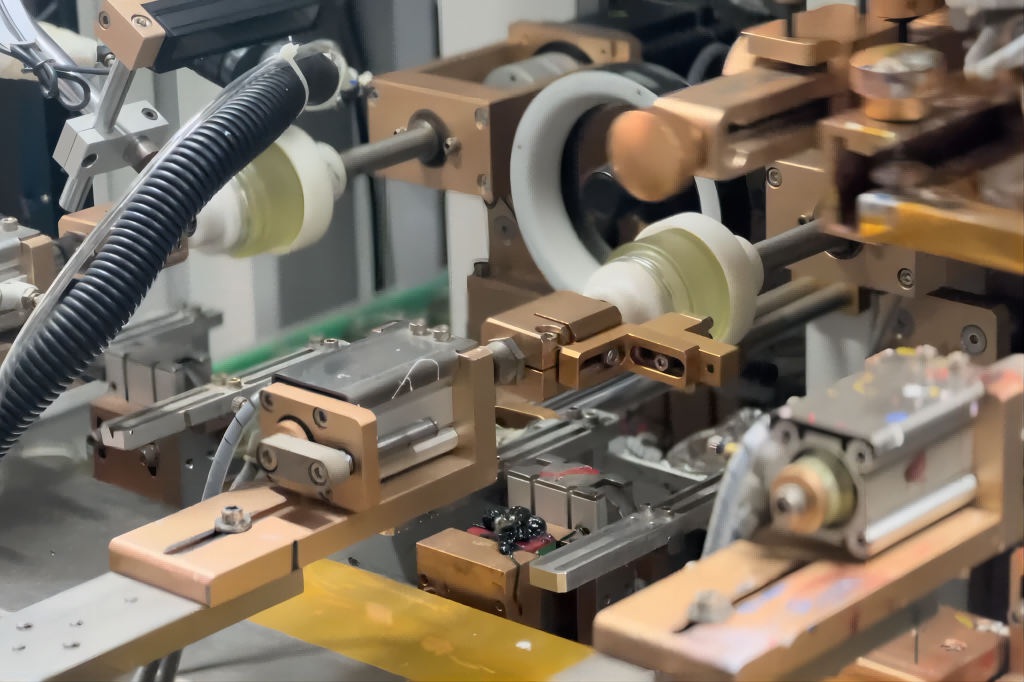

Hot Stamping

Cosmetic glass bottles with hot stamping use heat to apply metallic or colored foil to the glass. This process creates a premium look, often with a raised texture, making it popular for luxury branding.

Hot stamping is highly durable and adds a unique aesthetic. However, setup costs are high due to the foil materials and heat-stamping equipment. The production process is slower, and the color range is limited to metallics like gold or silver, making it less flexible for complex designs.

Pros | Cons |

|

|

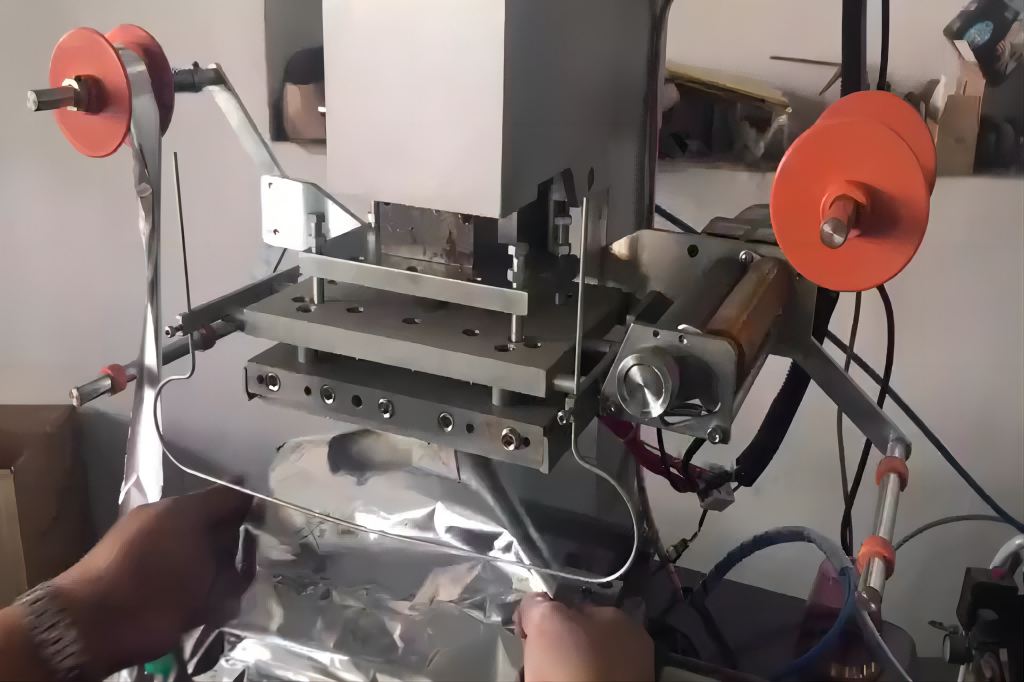

Laser Etching

Cosmetic glass bottles with laser etching are marked or engraved with a focused laser beam. This method creates permanent engravings that are extremely durable, with minimal environmental impact. It’s ideal for simple text, serial numbers, or small graphics, but generally lacks color and texture options.

Laser etching has high setup costs due to the specialized equipment, and while it is fast for simple designs, it can be slower for intricate patterns.

Pros | Cons |

|

|

Digital Printing

Cosmetic glass bottles with digital printing involve a digital printer that applies ink directly to the glass. This method supports high-resolution and complex multi-color designs, making it ideal for detailed branding and customization.

Digital printing is generally fast and has lower setup costs than UV printing or hot stamping. However, durability can be moderate, with prints susceptible to wear from frequent handling. Additionally, digital printing can require special inks, potentially affecting sustainability.

Pros | Cons |

|

|

Conclusion

Every printing technique for cosmetic glass bottles offers distinct advantages and disadvantages. When choosing the right technique, consider factors like design complexity, durability, cost, and environmental impact.

By understanding these five methods, brands can select the best printing technique to create eye-catching and durable cosmetic glass bottles that align with their branding goals and sustainability efforts.